Extrusion of Plastics: Forming the Future of Product Engineering

Plastic Extrusions: Explore the Large Range of Uses for Plastic Extrusions

Are you interested concerning the vast variety of usages for plastic extrusions? Look no more! In this article, we'll study the advantages, applications, developments, modification options, and ecological benefits of plastic extrusions.

Whether you remain in the building industry or simply curious about the most up to date technology, this article will certainly give you with beneficial understandings. - extrusion of plastics

Allow's explore the world of plastic extrusions with each other as well as uncover how they can transform different markets.

Benefits of Plastic Extrusions

You'll be pleased to understand that there are numerous benefits to making use of plastic extrusions in different markets. extrusion of plastics.

Plastic extrusions offer an even more budget friendly choice contrasted to various other materials like steel or timber. Furthermore, plastic extrusions can be easily customized to satisfy specific layout needs, saving you both time and money on production.

One more benefit of plastic extrusions is their adaptability. They can be formed right into different sizes and shapes, making them suitable for a vast array of applications. Whether you require basic layouts or intricate accounts, plastic extrusions can be customized to meet your specific needs. This versatility additionally permits for very easy assimilation with other parts, improving the total performance of your item.

Plastic extrusions use outstanding sturdiness and resistance to harsh environmental problems. They are immune to moisture, rust, and also uv rays, making them perfect for outside applications. Plastic extrusions likewise have reduced maintenance needs, reducing total operating expenses.

Finally, plastic extrusions offer many advantages for sectors across the board. From cost-effectiveness and also convenience to sturdiness and reduced upkeep, using plastic extrusions can considerably profit your business.

Applications in the Building Industry

There are many applications in the construction sector for plastic extrusions. These functional products have come to be a vital part in different building and construction tasks due to their durability, adaptability, and also cost-effectiveness.

One usual application of plastic extrusions in building and construction is in window and also door structures. Plastic extrusions offer a low-maintenance and also lightweight option to typical products like wood or steel. They are immune to rot, corrosion, and also weathering, making them suitable for exterior usage.

One more important use of plastic extrusions is in roof covering systems. Plastic extruded panels can be made use of for skylights, enabling natural light to enter the structure while keeping energy effectiveness. In addition, plastic extrusions are used for gutters as well as downspouts, supplying efficient drain remedies that are resistant to rust and leakages.

Plastic extrusions are likewise extensively utilized in the building and construction of dividings and walls. They can be used as walls, corner protectors, and attractive trims, boosting the overall visual charm of the structure. Plastic extrusions are easy to install as well as can be tailored to fit any kind of design requirements.

Technologies in Plastic Extrusion Technology

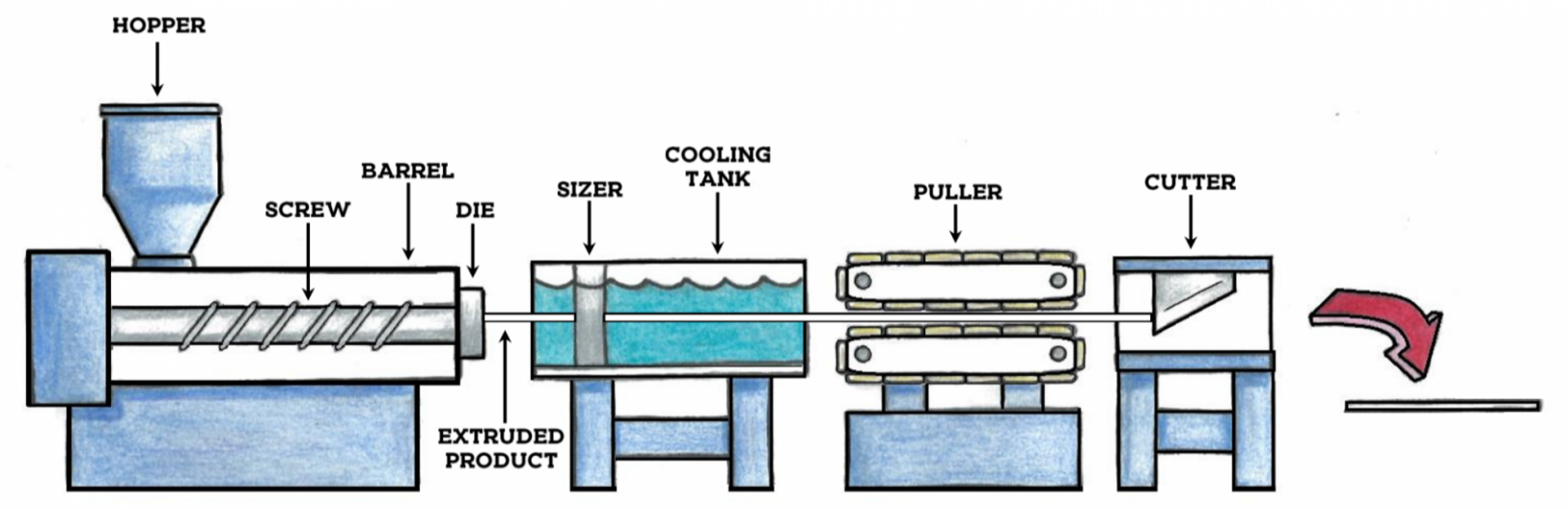

Among the most recent technologies in plastic extrusion technology is the growth of much more specific as well as reliable machinery. These developments have actually revolutionized the market, making it easier than ever to generate high-grade plastic extrusions for a variety of applications.

With the intro of these new equipments, you can currently achieve greater precision in the extrusion process. The machinery is equipped with innovative sensing units and also controls that permit even more accurate temperature level as well as pressure adjustments. This makes certain that the plastic is melted as well as shaped exactly as preferred, causing extrusions with consistent measurements and high architectural integrity.

In addition to enhanced precision, these machines also provide raised performance. They are developed to run at higher rates, enabling for faster production prices and much shorter preparations. This not just conserves time but also reduces expenses, making plastic extrusions a lot more economical for a large range of sectors.

Furthermore, these machines are furnished with sophisticated automation features, reducing the demand for hands-on intervention and lessening the risk of human error. This not only boosts the total quality of the extrusions yet additionally improves the safety and security of the drivers.

Personalization Options for Plastic Extrusions

With the schedule of adjustable choices, it's currently less complicated than ever before to tailor plastic extrusions to particular needs and also applications. Whether you need an unique form, dimension, or color, plastic extrusions can be personalized to meet your exact needs. You can pick from a range of materials, consisting of PVC, my explanation ABS, as well as HDPE, to guarantee that the extrusion appropriates for your specific application.

Among the main benefits of personalization is the capacity to produce complicated shapes as well as accounts. With innovative extrusion strategies, detailed designs can be achieved, permitting better convenience and also performance. From detailed tubing to facility channels, the opportunities are countless.

In enhancement to form customization, you can also customize the measurements of the extrusion. Whether you require a particular length, width, or thickness, plastic extrusions can be customized to meet your particular requirements. This makes sure a perfect fit for your application, eliminating the need for additional alterations or changes.

In addition, customization permits the inclusion of extra attributes and also discover here improvements. This includes the integration of unique additives, such as UV stabilizers or fire retardants, to boost the efficiency and sturdiness of the extrusion. In addition, you can integrate attributes like grooves, flanges, or openings to enhance capability and also ease of installation.

Environmental Benefits of Plastic Extrusions

By including recycled materials, plastic extrusions can contribute to a more lasting and also environment-friendly production process. When you choose plastic extrusions made from recycled products, you are aiding to lower the need for virgin plastic, which requires the extraction of non-renewable resources as well as adds to air pollution and also greenhouse gas discharges throughout manufacturing. By selecting recycled plastic extrusions, you are making a mindful option to support the circular economic situation and lower waste.

Along with using recycled products, plastic extrusions can also be recycled at the end of their life process. This indicates that the plastic can be thawed down and also reprocessed right into brand-new products, minimizing the quantity of plastic waste that finishes up in garbage dumps or contaminating our seas. By recycling plastic extrusions, you are assisting to conserve resources and also decrease the ecological impact of plastic production.

Additionally, plastic extrusions can be made to be energy-efficient, decreasing the energy consumption required throughout the manufacturing procedure. This not only helps to reduce carbon discharges yet also decreases prices and also makes the manufacturing process extra lasting.

Choosing plastic extrusions that are made from recycled materials and also can be recycled at the end of their life process is a reference straightforward yet reliable means to contribute to a much more lasting and also green manufacturing procedure. When you're taking into consideration plastic extrusions for your following job, bear in mind to prioritize sustainability and select materials that straighten with your ecological values.

Verdict

In conclusion, plastic extrusions use a plethora of benefits for different sectors, particularly building. With ingenious innovation, customization options, as well as ecological benefits, plastic extrusions give a flexible option for many applications.

From home window frames to piping systems, the uses for plastic extrusions are huge as well as remain to increase (extrusion of plastics). Whether you're looking for sustainability, longevity, or cost-effectiveness, plastic extrusions have actually got you covered.

Welcome the large range of opportunities as well as discover the advantages of plastic extrusions for your next task.

Are you interested about the broad array of usages for plastic extrusions? Plastic extrusions are likewise widely used in the construction of wall surfaces and dividers. When you pick plastic extrusions made from recycled products, you are helping to minimize the need for virgin plastic, which requires the removal of non-renewable sources and adds to contamination and also greenhouse gas exhausts throughout manufacturing. In addition to using recycled products, plastic extrusions can likewise be reused at the end of their life cycle. By recycling plastic extrusions, you are aiding to preserve sources as well as lower the environmental influence of plastic manufacturing.